Learn How Grease Traps Work in Wastewater Systems Title

Discover in detail how grease traps work in wastewater systems. The following article explains the operating principles, benefits, and popular types of grease traps such as grease interceptors, grease filters, sink grease traps, grease trap tanks, grease trap boxes, and grease trap containers. Find out why grease traps are an important solution for protecting drainage systems and reducing environmental pollution.

1. What Is a Grease Trap?

A grease trap (also known as a grease interceptor or grease separator) is a device designed to separate grease, oil, and solid particles from wastewater before it is discharged into the environment or sent to further treatment stages.

This device operates based on the principle of density difference: grease and oil are lighter than water, so they float to the surface and can be separated.

2. Operating Principles of Grease Traps

The operating principle of grease traps relies on the difference in specific gravity between grease and water. When wastewater flows into the grease trap, the separation process occurs in three main stages:

2.1 Grease Separation Stage:

-

-

When wastewater enters the grease trap, the flow slows down due to the trap’s structure, allowing grease, oil, and fats to float to the surface because they are lighter than water.

-

The grease and oil floating on the surface are retained, preventing them from entering the drainage system.

-

2.2 Heavy Particles Separation Stage:

-

-

-

While grease and oil float to the surface, heavier particles such as debris, sludge, and solid particles settle at the bottom of the grease trap.

-

These particles are retained in the sediment chamber of the grease trap, ensuring cleaner wastewater is discharged.

-

-

2.3 Clean Water Discharge Stage:

-

-

-

-

After grease, oil, and solid particles are separated, the remaining wastewater is discharged through the outlet.

-

The design ensures that discharged wastewater is free of grease or clogging substances, effectively protecting the drainage system.

-

-

-

3. Design Features of Grease Traps

-

Multi-Chamber Structure: Grease traps are often designed with multiple chambers to optimize grease separation and sedimentation. Each chamber has a specific function, from slowing down the flow to retaining particles.

-

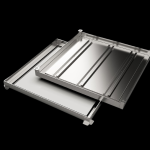

High-Quality Materials: Grease traps are commonly made from stainless steel, plastic, or non-corrosive steel, enhancing durability and resistance to moisture.

-

Easy Cleaning: Grease traps are designed with easy-to-open lids for convenient periodic cleaning to remove accumulated grease and debris.

4. Why Use Grease Traps?

Using grease traps in wastewater treatment systems is essential for protecting the environment and maintaining the efficiency of drainage systems. Here are reasons why grease traps, including grease interceptors, grease filters, sink grease traps, and grease trap tanks, are indispensable solutions:

4.1 Preventing Clogged Pipes:

Grease and oil in wastewater can easily accumulate in pipes, causing severe blockages.

Grease traps such as grease boxes or grease containers help remove these clogging substances.

4.2 Environmental Protection:

Wastewater containing grease and fats can pollute the environment and affect natural ecosystems.

Grease traps reduce harmful waste discharge, contributing to environmental protection.

4.3 Saving Maintenance Costs:

Pipe blockages often lead to high repair costs, ranging from $20 to $40 per repair. Grease traps reduce this risk, saving maintenance costs. Installing sink grease traps in kitchens at home or in restaurants helps maintain system stability.

4.4 Compliance with Environmental Regulations:

Many areas require businesses such as restaurants, hotels, or factories to install grease traps for wastewater treatment before discharge.

5. Benefits of Grease Separation Protecting Drainage Systems:

-

Protecting Drainage Systems: Prevents grease and debris accumulation, reducing pipe blockage risks.

-

Protecting the Environment: Removes grease and fats, minimizing environmental pollution and improving wastewater quality.

-

Saving Costs: Reduces repair and maintenance costs due to blockages.

For more details or advice on choosing and using grease traps effectively, please contact hotline: 0368172226 / 0834473166 or visit the website atnewtech.vn. We are always ready to assist you.

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank