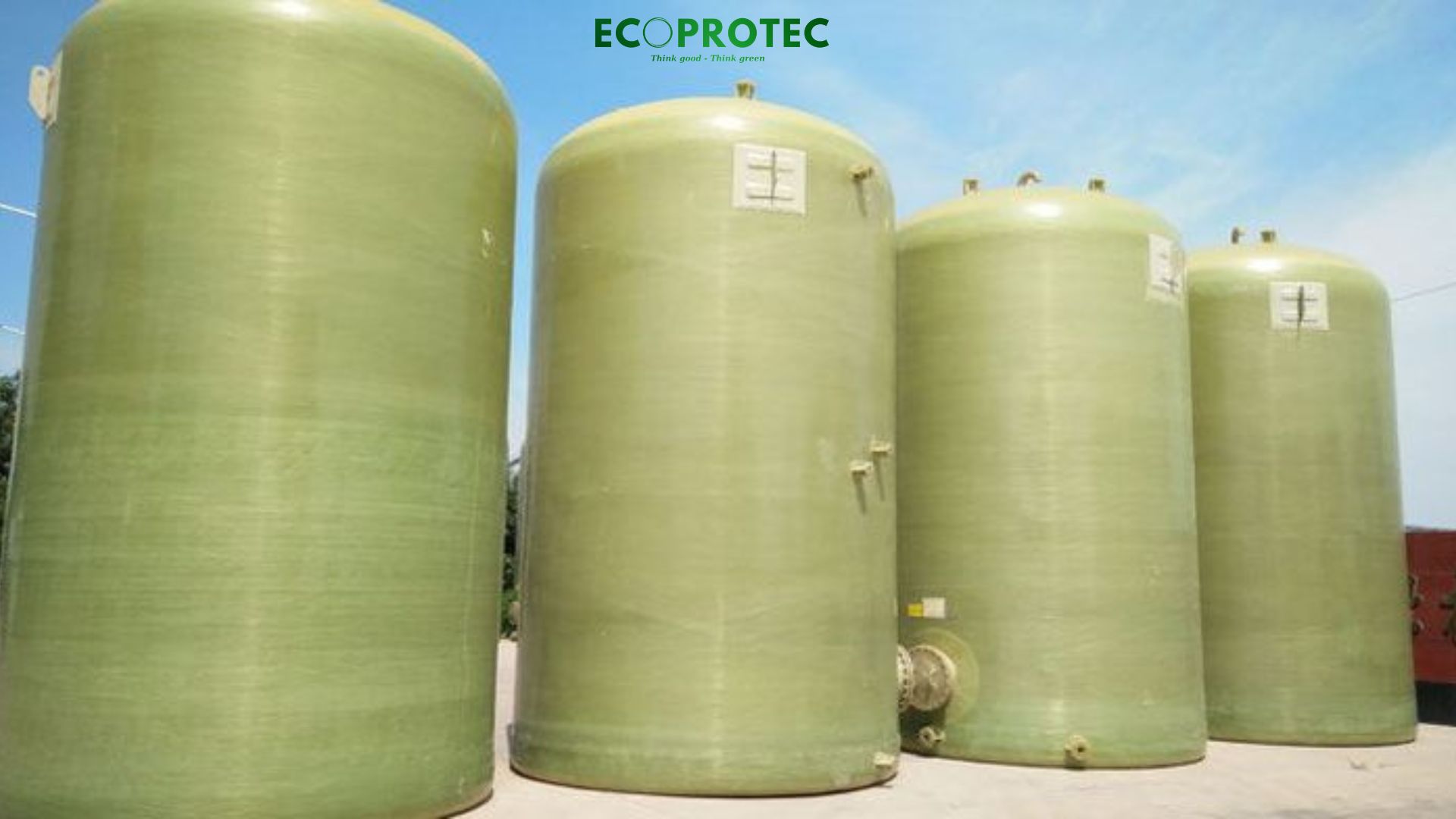

How to Choose the Right FRP Chemical Storage Tank for Acids and Alkalis

If you’re looking for a safe, durable, and cost-effective solution to store acids or alkalis in factories, industrial zones, or manufacturing facilities, choosing the right chemical storage tank is a critical factor. Among the available options, FRP (Fiberglass Reinforced Plastic) composite tanks are increasingly favored thanks to their excellent corrosion resistance — making them especially suitable for storing acids like H₂SO₄ or strong alkaline solutions. This article provides a detailed guide to help you select the most appropriate FRP chemical tank, ensuring safety while optimizing investment costs.

1. Overview of Chemical Storage Tanks and Their Importance in Industry

1.1 What is a Chemical Storage Tank?

Chemical storage tanks are specialized equipment used to store highly corrosive liquids such as acids (H₂SO₄, HCl, HNO₃…), alkalis (NaOH, KOH…), or toxic and volatile substances. They are widely used in industries such as:

-

Chemical and pharmaceutical production

-

Industrial wastewater treatment

-

Food and pharmaceutical processing

-

Petrochemical refining and electroplating

-

Mining, fertilizer, and surface treatment

1.2 Why Is It Important to Choose the Right Tank?

Choosing the wrong type of tank can lead to severe consequences:

-

Rapid corrosion and chemical leakage

-

Fire hazards or health risks

-

High maintenance and replacement costs

-

Failure to meet environmental safety standards

2. Introduction to FRP Composite Chemical Storage Tanks

2.1 What Is FRP Composite Material?

FRP (Fiberglass Reinforced Plastic) is a composite material made from a resin matrix (such as Vinyl Ester, Epoxy, or Polyester) reinforced with fiberglass. Advantages:

-

Exceptional chemical resistance

-

Lightweight and easy to transport

-

Non-conductive and excellent thermal insulation

-

Long service life with low maintenance costs

2.2 Why Are FRP Composite Tanks Preferred?

Compared to stainless steel tanks or HDPE plastic tanks, FRP chemical tanks offer superior advantages, particularly in environments involving strong acids and high-concentration alkalis:

-

Unlike stainless steel, FRP is not corroded by HCl or H₂SO₄

-

More durable than standard plastic tanks

-

Flexible in design: vertical, horizontal, cylindrical, rectangular — with optional UV protection or heat-resistant coatings

3. Types of Chemical Storage Tanks by Application

3.1 Acid Storage Tanks

-

Stored chemicals: H₂SO₄, HCl, HNO₃…

-

Required material: Vinyl Ester FRP or Epoxy FRP for strong corrosion resistance

-

Design features: UV-protected exterior coating, safety valves, and pressure sensors

3.2 Sulfuric Acid (H₂SO₄) Storage Tanks

-

Concentrated sulfuric acid is extremely corrosive

-

Requires special FRP liners designed for H₂SO₄ resistance

-

Tanks must be designed to handle high pressure and temperature

3.3 Alkali Storage Tanks

-

Stored chemicals: NaOH, KOH, NH₄OH…

-

Required material: Polyester FRP with good alkali resistance

-

Compatible with PVC or PP accessories for added safety

4. Criteria for Selecting a Suitable FRP Chemical Storage Tank

4.1 Based on the Type of Chemical Stored

| Chemical Type | Concentration | Recommended Material |

| H₂SO₄ ≥ 98% | Concentrated | Vinyl Ester FRP |

| HCl | 30 – 37% | Epoxy FRP |

| NaOH | 20 – 50% | Polyester FRP |

| Nitric Acid | ≤ 60% | Vinyl Ester FRP |

Note: Each acid or alkali has unique chemical properties. Always provide the MSDS (Material Safety Data Sheet) of the chemical to the supplier for accurate consultation.

4.2 Required Capacity

-

<1m³: Suitable for laboratories or small-scale production

-

1 – 10m³: Ideal for medium-sized production lines

4.3 Installation Location

-

Indoor: Prefer FRP tanks with UV-resistant coatings to reduce discoloration

-

Outdoor: Reinforce with support frames, sunshades, and bottom drainage system

4.4 Additional Features

-

Chemical level sensor

-

Standard chemical inlet/outlet ports

-

Safety valves, stainless steel or chemical-resistant plastic flanges

-

Anti-slip base and overload protection

5. Comparison: FRP Composite Tank vs. Other Tank Materials

| Criteria | FRP Composite Tank | Stainless Steel Tank (316/304) | HDPE/PP Plastic Tank |

| Corrosion resistance | Very high (strong acids, alkalis) | Medium (not suitable for HCl, H₂SO₄) | Low (degrades under strong chemicals) |

| Service life | 15 – 20 years | 5 – 10 years | 3 – 5 years |

| Weight | Lightweight | Heavy | Lightweight |

| Custom design flexibility | Highly customizable | Limited | Moderate |

| Cost | Medium – cost-effective | High | Low |

✅ Conclusion: FRP chemical storage tanks are the optimal choice in terms of safety, durability, and cost-efficiency.

6. Purchasing and Production Process at ATnewtech

6.1 Technical Consultation Based on Chemical Type

-

Submit MSDS or chemical details

-

Our engineers will recommend the appropriate FRP material

6.2 Custom Design

-

Technical drawings provided

-

Accessories included: lids, sensors, valves, flanges…

6.3 Manufacturing & Quality Testing

-

Produced according to ISO standards

-

Tested for leakage and chemical resistance

6.4 Delivery & Installation

-

Free delivery within Ho Chi Minh City

-

On-site installation, handover, and usage instruction

7. Warnings and Notes When Using FRP Chemical Tanks

-

Never store chemicals that are incompatible with the tank’s original design

-

Do not drill or modify the tank structure without manufacturer approval

-

Inspect every 3–6 months to detect early signs of corrosion

-

Equip staff with full safety gear when handling chemicals

8. Who Should Use FRP Composite Chemical Storage Tanks?

-

Industrial wastewater treatment plants

-

Fertilizer and chemical manufacturing facilities

-

Electroplating, metal finishing, and precision mechanical workshops

-

Schools, hospitals, research institutes storing chemicals

-

Urban and industrial zone chemical treatment systems

9. Why Choose Ecoprotec FRP Chemical Tanks by ATnewtech?

-

Imported materials with excellent chemical resistance

-

Precision-manufactured using modern molding techniques

-

Wide capacity range: from 500L to 100m³

-

Competitive pricing with special offers for large projects

-

Lifetime technical support

-

Up to 5-year warranty

10. Get a Free Consultation & Quotation Today

💡 Don’t let chemical corrosion damage your system! Invest smart from the beginning with high-quality FRP composite chemical tanks from ATnewtech.

📞 Technical Support Hotline: 0834 473 166🌐 Website: https://atnewtech.vn📍 Address: [To be updated as needed]

Meta Title: How to Choose the Right FRP Chemical Storage Tank for Acids and Alkalis | ATnewtech

Meta Description: Detailed guide on selecting the right chemical storage tank for acids and alkalis such as H₂SO₄, HCl, NaOH. Discover the benefits of FRP composite tanks – the safe, cost-effective, and durable solution for all industries. Hotline: 0834473166

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank