Guide to Choosing the Right Grease Separator for Your Restaurant Based on Kitchen Size

If you’re running a restaurant, eatery, or industrial kitchen and are concerned about grease causing blockages in the drainage system, a restaurant grease separator is the optimal solution for effectively handling waste grease, protecting the drainage system, and ensuring environmental hygiene. However, not everyone knows how to choose the right grease trap for their kitchen size. In this article, we will guide you on how to select the most suitable grease separator for your restaurant, ensuring smooth kitchen operations and cost savings.

1. What is a Restaurant Grease Trap?

A restaurant grease separator (also known as a grease trap, grease treatment device, or grease collection tank) is an essential wastewater treatment device for industrial kitchens. The main function of the grease separator is to separate grease and solids from wastewater, helping protect the drainage system, preventing blockages, and reducing environmental pollution.

2. Why Do Restaurants Need a Grease Separator?

-

Prevent Drain Blockages: Grease that is not treated will accumulate and cause severe blockages in pipes.

-

Comply with Environmental Regulations: Treating wastewater containing grease helps restaurants meet environmental hygiene regulations.

-

Save Maintenance Costs: Minimizes costs for clearing blockages and pipe repairs.

-

Ensure Cleanliness and Food Safety: Removing grease keeps the kitchen clean and prevents bacteria growth.

3. How to Choose the Right Grease Separator for Your Restaurant

Choosing the right grease separator not only ensures an efficient drainage system but also helps save costs and comply with environmental regulations. To select the optimal product, several important factors must be considered, such as capacity, material, installation location, and additional features.

3.1. Determine Kitchen Size

Each restaurant or eatery has a different kitchen size, so it’s essential to choose a grease trap with the appropriate capacity:

-

Small Kitchens (small eateries, cafes with small kitchens): Choose a grease separator with a capacity of 40-50L.

-

Medium-Sized Restaurants (serving 50-200 meals/day): Choose a grease separator with a capacity of 50-200L.

-

Industrial Kitchens, Large Restaurants (serving over 200 meals/day): A grease separator with a capacity over 200L or a large-scale grease separation system is required.

3.2. Choose the Right Material

The material of the grease separator affects its durability and efficiency. Here are some factors to consider when choosing the material:

-

Strength and Corrosion Resistance: Since industrial kitchens are exposed to many chemicals and grease, it’s important to choose a durable separator.

-

Ease of Cleaning: Stainless steel grease traps are usually easier to clean than composite plastic ones.

-

Initial Investment Cost: Stainless steel grease traps are more expensive but have a longer lifespan, while composite plastic ones are cheaper but less durable.

-

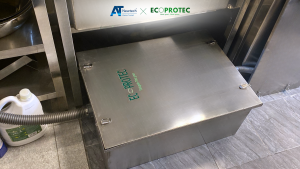

Stainless Steel Separator: High durability, excellent corrosion resistance, easy to clean.

-

Composite Plastic Separator: Lightweight, more affordable, but still effective for grease separation.

3.3. Determine Installation Location

Choosing the right installation location enhances the effectiveness of the grease separator in your restaurant. Common installation locations include:

-

In the kitchen, under the sink: Convenient for small to medium-sized kitchens, allowing grease to be treated right at the source.

-

Outdoors, near the main drainage area: Suitable for large restaurants or industrial kitchens with a high volume of wastewater.

-

In a basement or sewage pit system: Ideal for kitchens with specialized drainage systems, helping separate grease effectively and making maintenance easier.

Additionally, when installing, ensure that the grease separator has an appropriate slope to allow wastewater to flow evenly and prevent stagnation, which could lead to unpleasant odors.

4. Installation and Maintenance Guide for Grease Separators

4.1. Installation Instructions

-

Install the grease trap in a location that allows for easy cleaning and maintenance.

-

Ensure proper connection of the inlet and outlet pipes.

-

Check the slope and wastewater flow to ensure efficient operation.

4.2. How to Maintain and Clean

-

Regular Cleaning: Remove grease and debris at least 1-2 times a week.

-

Check the Pipe System: Prevent leaks or blockages.

-

Use Microbial Grease Treatment: This helps break down grease more effectively.

-

Where to Buy a Reliable Restaurant Grease Separator?

If you are looking for a high-quality grease separator for your restaurant, please contact us today:

Hotline: 0368172226 / 0834473166 Website: atnewtech.vn

We are committed to providing high-quality, durable, and effective restaurant grease separators that protect the drainage system and enhance kitchen efficiency.

We hope this article has provided you with useful knowledge to help you choose the right grease trap for your restaurant. Don’t let grease disrupt kitchen operations – invest in a restaurant grease separator now to protect your drainage system and save on operational costs!

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank