Grease Trap Technology for Modern Grease Treatment

In modern life, the issue of treating leftover grease from residential and industrial activities is a significant concern. Specifically, grease discharged from kitchens, restaurants, eateries, or production facilities, if not properly treated, can cause severe environmental pollution. Hence, grease traps, grease separators, or oil interceptors have been developed as optimal solutions for effectively and environmentally friendly grease treatment. Join AT Newtech to delve into the details of various types of grease traps and their operation!

1. What Is a Grease Trap?

A grease trap, also known as a grease separator, is a specialized device designed to separate grease and oil from wastewater. This device is typically installed under sinks, in drainage systems, or in areas requiring grease-laden wastewater treatment. With its ability to remove grease effectively, grease traps play a vital role in protecting drainage systems and the surrounding environment.

2. Types of Grease Traps

2.1. Classification by Usage

For Families

-

Sink Grease Trap: This type of grease trap is compactly designed, suitable for placement under sinks in households. With its ability to handle moderate grease volumes, it helps protect drainage systems and effectively prevents blockages.

-

Grease Trap Box: Ideal for small families or kitchens with limited space, these grease trap boxes are easy to install and clean, ensuring effective grease treatment.

For Restaurants and Eateries

-

Grease Trap Tank: Designed with a larger capacity, this type of grease trap is suitable for restaurants and eateries with high grease-laden wastewater flow. It ensures stable operation and reduces maintenance costs for the drainage system.

-

High-Tech Grease Separator: High-end restaurants and hotels often choose grease traps integrated with automatic technology, such as full-tank sensors and multi-layer filtering systems, to optimize grease treatment efficiency and save operation time.

For Factories and Industrial Zones

-

Grease Trap Tank: These are specialized solutions for factories and industrial zones with large volumes of wastewater. They are designed for large-scale grease treatment, comply with environmental standards, and support sustainable operations.

2.2 Classification by Material

Stainless Steel

-

Features: Stainless steel ensures durability, corrosion resistance, and ease of cleaning. It is a popular choice for restaurants, hotels, and industrial zones.

-

Benefit

-

Long lifespan.

-

Resistant to high temperatures and chemicals.

-

Ensures food safety and hygiene standards.

-

High-Quality Plastic

-

Features: Grease traps made from high-quality plastic are generally more affordable, lightweight, and easy to install. They are commonly used in households or small eateries.

Composite grease traps are a popular choice for eateries, restaurants, and industrial kitchens.

-

Benefit

-

Lightweight and portable.

-

More affordable than stainless steel.

-

Excellent water resistance.

-

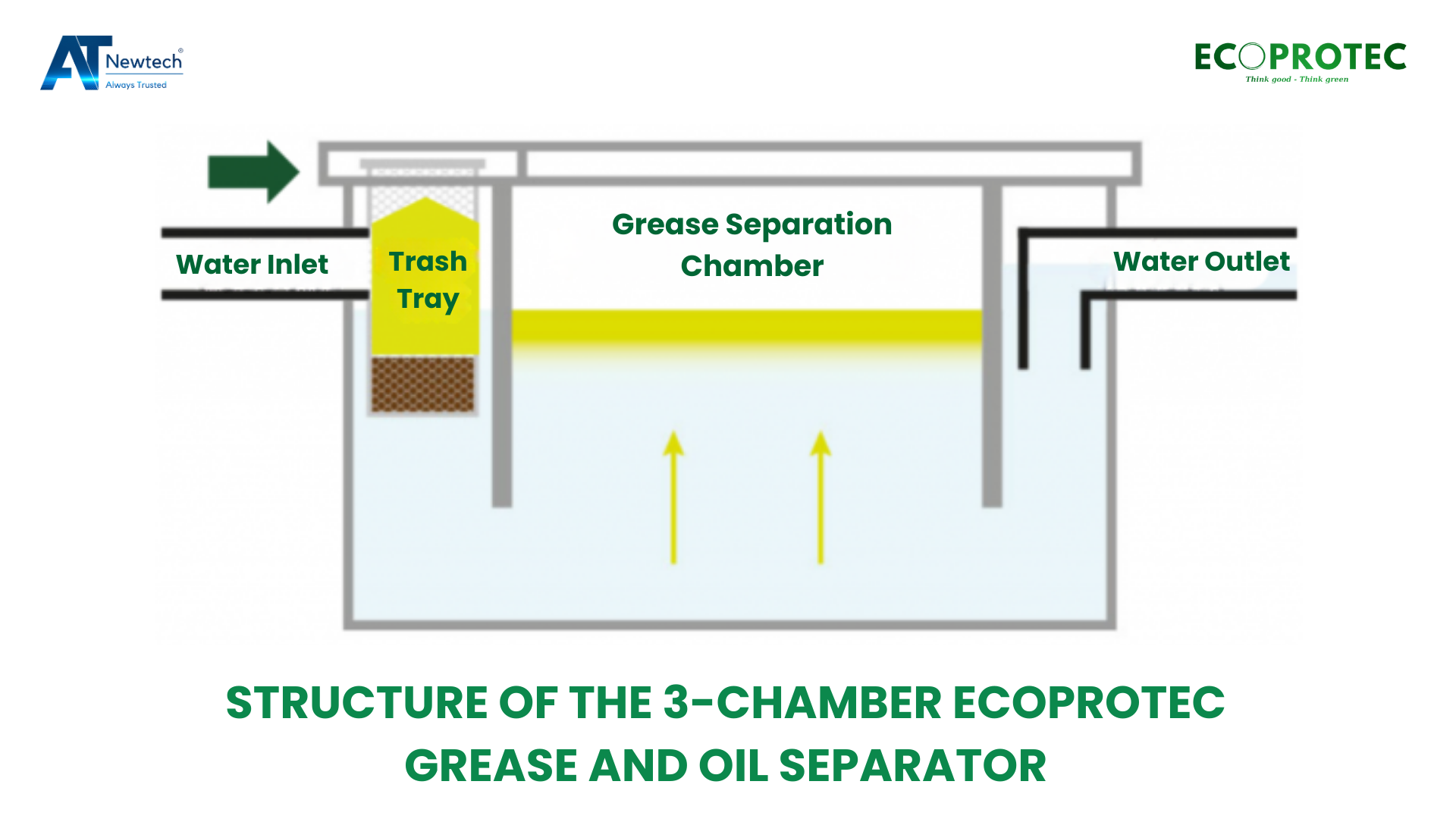

3. Operating Principles

-

Grease Separation: When wastewater containing grease enters the grease trap, thanks to its special internal structure, grease and oil (being lighter than water) float to the surface and are retained. Cleaner water flows out.

-

Sedimentation: Modern grease traps are equipped with multi-layer filtering systems to ensure maximum grease and contaminant removal. Small grease particles and other impurities settle at the bottom or are trapped in sedimentation compartments.

4. Applications of Advanced Technology

-

Automated Systems: Some grease separators are equipped with automatic full-tank sensors, making it easier for users to monitor and maintain the device.

-

Grease Recycling Capability: Some high-end grease traps can recover grease for reuse in energy production or other products.

5. Benefits of Using Grease Traps

-

Protects Drainage Systems: Minimizes blockages and damage to pipes.

-

Environmental Protection: Prevents grease from entering water sources, reducing pollution risks.

-

Cost Savings: Reduces maintenance and repair costs for drainage systems.

-

Enhanced Operational Efficiency: Helps businesses like restaurants and hotels operate smoothly without wastewater issues.

6. How to Choose the Right Grease Trap

When selecting a grease trap, consider the following factors:

-

Capacity: Choose a capacity suitable for the volume of grease and wastewater.

-

Material: Decide between stainless steel or high-quality plastic based on your budget and needs.

-

Size: Measure the installation space to choose a product with the appropriate size.

-

Supplier: Choose a reputable supplier to ensure product quality and after-sales service.

7. Why Choose Ecoprotec’s Grease Traps?

Ecoprotec is proud to be a leading provider of grease treatment solutions, offering high-quality products such as grease traps, grease filters, grease separation tanks, grease trap boxes, and grease trap bins. We commit to:

-

A diverse range of products, suitable for all needs.

-

Competitive and reasonable prices.

-

Dedicated consultation and technical support services.

-

Long-term warranties to ensure customer peace of mind.

Contact Us for Consultation Today!

If you are looking for effective grease treatment solutions, contact us now via:

-

Hotline: 0368172226 / 0834473166

-

Website: atnewtech.vn

The expert team at Ecoprotec is always ready to support you anytime, anywhere!

We hope this article has provided you with an overview of the types of grease traps and the importance of using grease traps in wastewater treatment. Let AT Newtech accompany you on your journey to protect the environment and improve quality of life!

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank