Do FRP Composite Chemical Storage Tanks Offer UV Protection? In-Depth Explanation

Do FRP Composite Chemical Storage Tanks Offer UV Protection? This is a common question among businesses needing outdoor tank installation. The following article provides an in-depth analysis of the UV resistance of composite tanks and the risks if UV protection is not handled properly—especially when storing strong acids like H₂SO₄. Join ATnewtech to discover the optimal, safe, and cost-effective long-term solution.

1. The Dangers of UV Rays to Chemical Storage Tanks – Why It Matters

In outdoor environments, UV rays (ultraviolet) from sunlight can seriously damage plastic materials, especially without proper protective coatings. For chemical storage tanks—which hold acids, alkalis, industrial solvents—UV exposure can lead to:

-

Rapid aging, brittleness, and surface cracking

-

Reduced chemical resistance

-

Dangerous chemical leaks and compromised safety

Thus, for outdoor chemical storage tanks—especially sulfuric acid (H₂SO₄) tanks—UV resistance is a critical feature that must not be overlooked.

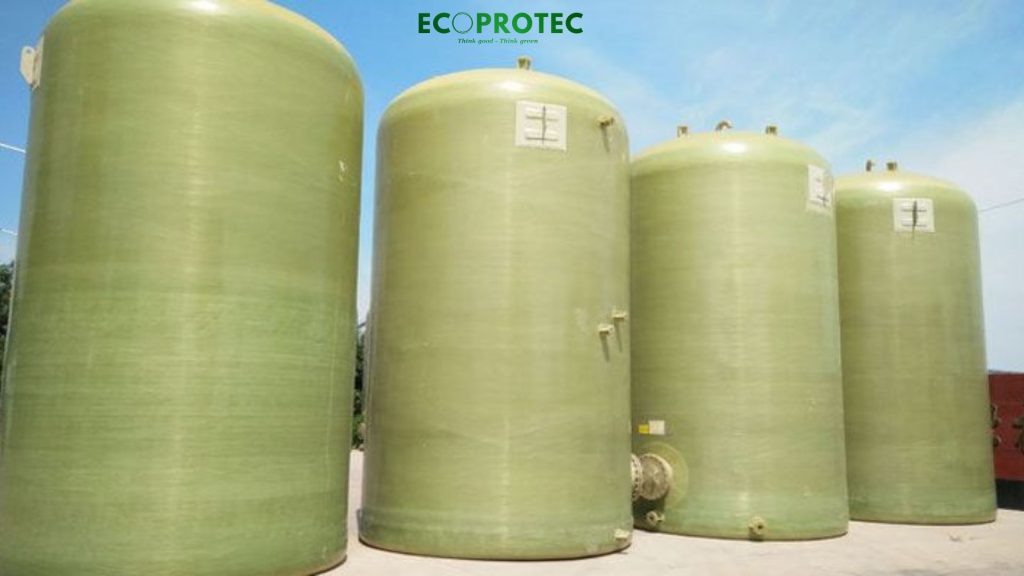

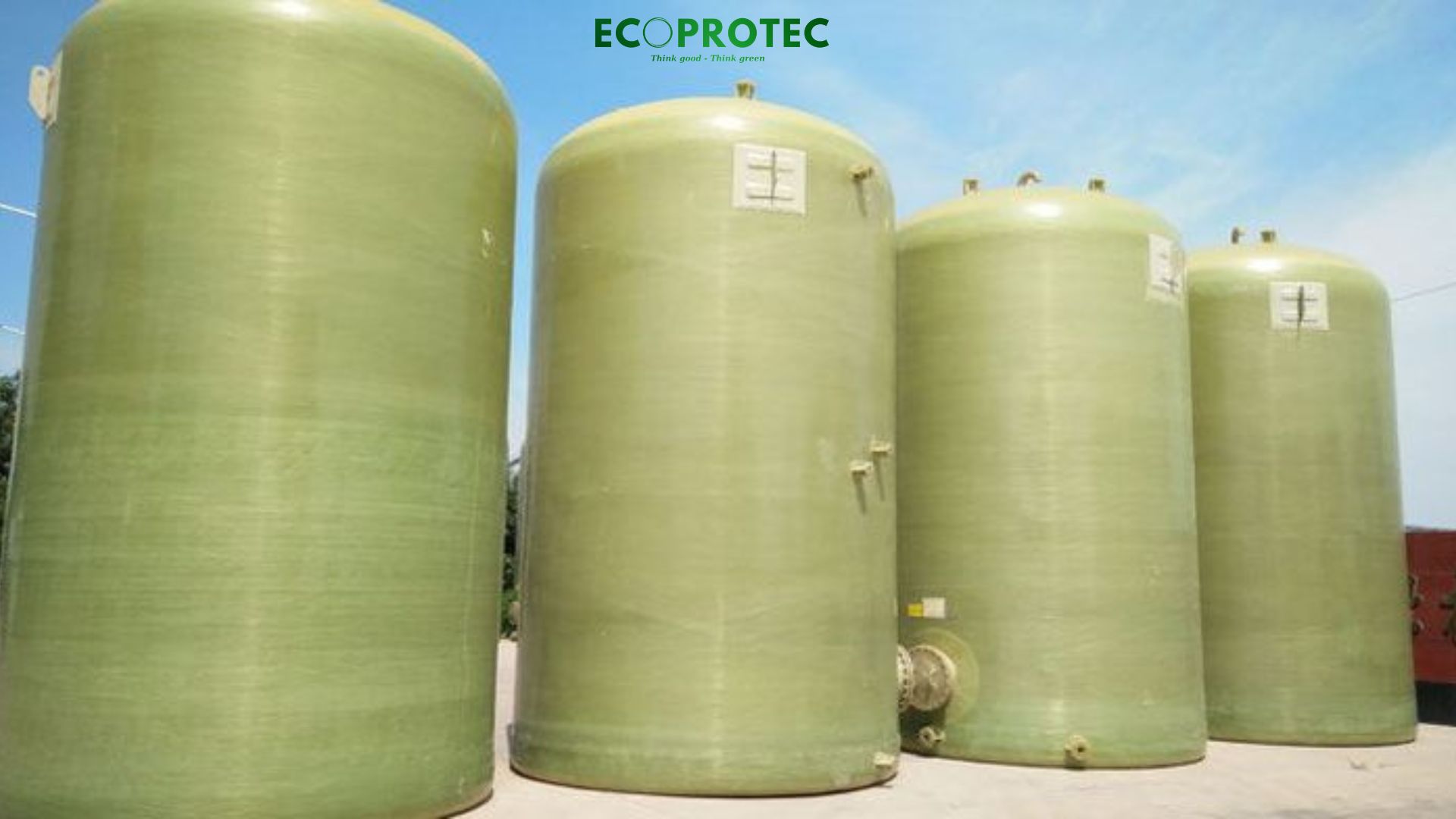

2. Structure of FRP Composite Chemical Tanks and the UV Protection Layer

FRP (Fiberglass Reinforced Plastic) composite tanks typically consist of three main layers:

-

Inner liner layer: Directly contacts the chemical, made from corrosion-resistant resins like Vinyl Ester, Epoxy, or Polyester.

-

FRP reinforcement layer: A mix of resin and fiberglass for strength and rigidity.

-

Outer protective layer: Guards against environmental factors such as UV rays, heat, and moisture.

The outer layer is usually made with UV-stabilized gelcoat or PU/Epoxy coatings that reflect sunlight and resist UV degradation.

3. Are Outdoor FRP Chemical Storage Tanks UV-Resistant?

Yes. If produced with proper techniques and materials, composite tanks can offer excellent UV protection when using:

-

UV-resistant gelcoat

-

Base resin containing UV stabilizers

-

Light-colored outer layers (white, gray) to reflect heat and sunlight. Such designs allow the tanks to last 15–20 years outdoors.

However, not all composite tanks include this feature. Low-cost tanks often lack UV coating and may degrade after only 3–5 years.

4. Risks of Using Composite Tanks Without UV Protection

-

Bubbling, cracking, or crazing on the surface

-

Exposed fiberglass, prone to mold and corrosion

-

Reduced chemical resistance, especially to strong acids like H₂SO₄

-

Leaks → endangering people and the environment

-

High repair and maintenance costs

5. Should You Use FRP Composite Tanks for Storing H₂SO₄ Outdoors?

The answer is YES, provided the tank meets the following conditions:

-

Made with Vinyl Ester resin + UV stabilizers

-

Outer gelcoat with certified UV resistance rating

-

Designed with protective roofs or light-colored surfaces

-

Equipped with safety valves, pressure sensors if used in high-temperature areas

With H₂SO₄—an extremely corrosive acid—ensuring UV durability of the outer layer is crucial for long-term safety.

6. How to Inspect and Maintain the UV Protection Layer of Chemical Tanks

Regular inspection:

-

Visual check: Look for early signs of cracks or peeling on the surface

-

Measure gelcoat thickness using specialized equipment

-

Color evaluation: Fading or yellowing indicates UV protection degradation

Maintenance:

-

Clean the tank surface regularly with mild soap

-

Reapply gelcoat or a new UV-resistant PU coating every 3–5 years

-

Inspect joints and flanges to ensure airtight seals and prevent chemical leaks

7. Comparison: UV-Resistant vs. Non-UV-Resistant Composite Tanks

| Criteria | UV-Resistant Composite Tank | Non-UV-Resistant Composite Tank |

| Outdoor lifespan | 15–20 years | 3–7 years |

| Surface durability | No cracking, retains color | Fades easily, prone to cracks |

| Chemical resistance | Long-lasting | Decreases over time |

| Maintenance cost | Low, minimal upkeep | High, frequent restoration needed |

8. Technical Considerations When Buying Outdoor Chemical Tanks

-

Ask for UV stabilizer specs and gelcoat type used

-

Prefer Vinyl Ester resin over Polyester for better acid resistance

-

Choose reputable suppliers like ATnewtech with certifications and sample testing

-

Ensure the tank design suits the installation site: indoor, outdoor, or under a canopy

9. ATnewtech’s Solution: Specialized UV-Resistant FRP Composite Tanks

-

Free consultation on the right tank based on chemical type, concentration, and site conditions

-

Supply of high-grade gelcoat UV-resistant composite tanks

-

On-site installation service with optional protective roofing

-

Scheduled UV coating maintenance and reapplication service

Hotline: 0834473166 | Website: https://atnewtech.vn

10. Frequently Asked Questions – UV Resistance in Chemical Storage Tanks

Do composite tanks resist UV rays?

Yes, if made with proper UV-resistant materials and coatings.

How often should the gelcoat UV layer be repainted?

Every 3–5 years, depending on weather conditions and usage environment.

Can H₂SO₄ storage tanks be installed outdoors?

Yes, but only if made from UV-resistant and acid-resistant FRP composite.

11. How to Choose a Long-Lasting Composite Chemical Tank?

If your business requires chemical storage tanks, especially for outdoor use, prioritize:

-

Composite tanks with certified UV-resistant layers

-

Vinyl Ester resin specially designed for acids like H₂SO₄

-

Reliable manufacturers like ATnewtech who offer full-package services: design, installation, and maintenance

This solution ensures long-term performance, safety, and significant cost savings over time.

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank