Comprehensive FRP Composite Tank Solutions – Absolute Waterproofing & Long-Lasting Durability

In an era of increasingly strict environmental standards, both residential and industrial projects require safe, sustainable, and cost-effective water treatment and storage systems. FRP (Fiberglass Reinforced Plastic) composite tanks are becoming the preferred solution, thanks to their superior advantages over concrete, stainless steel, or conventional plastic tanks.

✅ Key Advantages of FRP Composite Tanks:

- Absolute corrosion and leak resistance

- Ultra-durable – Lifespan up to 50–60 years

- Lightweight – Easy to transport and install

- No rust, no cracking like concrete tanks

- Customizable sizes and configurations

🛠 FRP Composite Products by ATNEWTECH (An Tâm Newtech)

1. FRP Septic Tanks

Composite septic tanks are primary wastewater treatment systems widely used in homes, villas, apartment complexes, factories, schools, hospitals, and industrial zones.

- Main functions: Collecting, settling, and treating domestic wastewater from toilets before discharge to centralized systems or the environment.

- Material: FRP with fiberglass reinforcement, offering high strength, chemical resistance, and absolute waterproofing. Unlike traditional concrete tanks, FRP tanks do not crack, settle, or leak.

- Structure: A sealed design with 2 or 3 chambers (collection – sedimentation – filtration), based on anaerobic principles to efficiently break down organic waste.

- Common capacities: From 500L to 10m³, suitable for both small homes and large-scale buildings. Installation options include aboveground or underground setups depending on site design.

|

|

|

|

- Benefits:

- Fast installation – No concrete work, no waterproofing needed

- Cost-effective – Saves labor and materials

- Lightweight – Ideal for tight spaces or soft ground conditions

- Easily integrated into central wastewater treatment systems

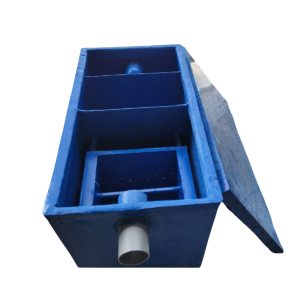

2. FRP Grease Trap Tanks

Industrial FRP grease traps are essential pre-treatment units installed in the wastewater system of restaurants, industrial kitchens, hotels, canteens, and any building with high grease discharge.

- Main function: Separate grease, oil, and food solids from wastewater before discharge, protecting plumbing systems and the environment.

- Material: Durable FRP composite with fiberglass, resistant to corrosion, moisture, and exposure to light chemicals and grease – ideal for greasy, wet conditions.

- Structure: Typically features 3 compartments (solids settling – grease separation – post-separation), removable waste basket, airtight lid with gasket, and strategically placed inlet/outlet pipes for optimal performance.

- Common capacities: From 100L to 2000L+, adaptable for various installation styles: floor-mounted or underground based on project needs.

|

|

|

|

|

- Advantages:

- ✅ Lightweight and easy to transport/install

- ✅ No waterproofing required like concrete tanks

- ✅ Long-lasting durability with simple maintenance

- ✅ Cost-effective compared to stainless steel or concrete tanks

3. Underground Composite Water Tank

The underground composite-lined stainless steel water tank is a clean water storage solution installed beneath building foundations. It is widely used in residential houses, villas, hotels, schools, factories, apartment complexes, and infrastructure projects.

- Main function: Stores domestic water or fire protection reserve water, ensuring a stable water supply for the building.

- Structure:

- Inner core made of SUS 304 stainless steel, ensuring food-grade safety, rust resistance, and no harmful substance leaching into the water.

- Outer shell reinforced with FRP (Fiberglass Reinforced Plastic): offers excellent strength, corrosion resistance, waterproofing, and thermal insulation.

- Equipped with a tight-fitting lid, overflow pipe, ventilation pipe, and maintenance hatch for easy installation and servicing.

|

|

|

|

- Outstanding advantages:

- Sustainable and Long-Lasting over 20 Years of Durability

- No leakage or seepage issues like traditional concrete tanks

- Easy to clean and maintain water quality

- Fast installation, saving cost and space

- Available capacities: from 1m³ to several tens of m³, customizable per project scale

Ideal for: Projects with strict water quality standards, long service life, low maintenance requirements, and locations with weak foundations or waterproofing demands

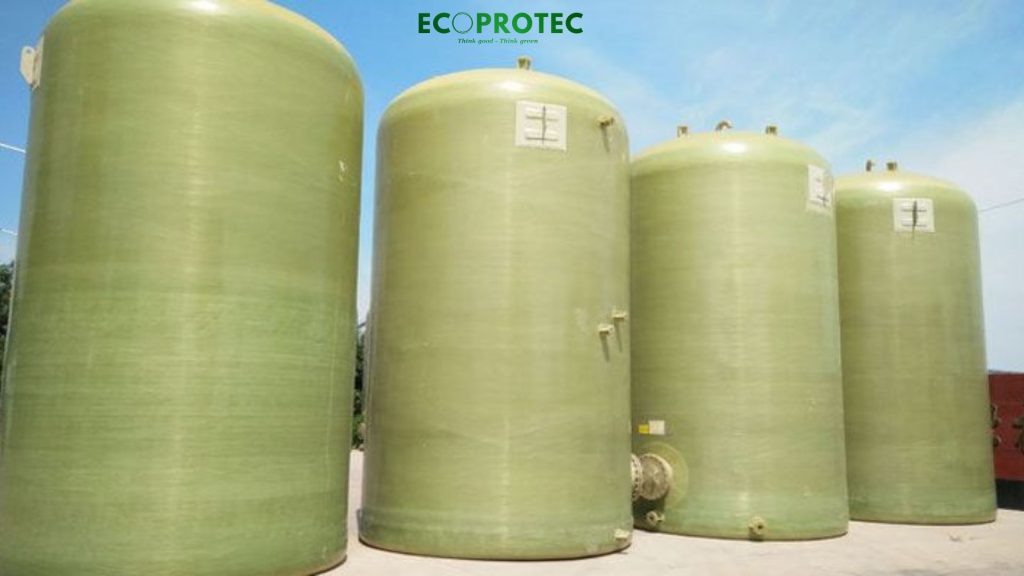

4. Composite FRP Chemical Storage Tanks

ATNewtech’s composite chemical tanks are manufactured from premium FRP (Fiberglass Reinforced Plastic), offering outstanding resistance to chemical corrosion, heat, and mechanical impact. These tanks are widely used in industries such as: Chemical manufacturing, Wastewater treatment, Electroplating, Pharmaceuticals, Food processing, And any application requiring secure storage of corrosive or sensitive substances.

|

|

|

|

-

Outstanding advantages:

-

Superior corrosion resistance, ensuring chemical safety and long service life

-

Robust structure, suitable for high pressure and harsh environments

-

Flexible design, with a wide range of capacities and shapes tailored to requirements

-

Lightweight, for easy transport and installation

-

Low maintenance, reducing long-term operational costs

ATNewtech guarantees safe, durable, and cost-effective chemical storage solutions, backed by strict manufacturing standards.

-

5. FRP Waterproofing & Coating for Tanks, Factory Floors, and Rooftop Surfaces

-

Purpose: To enhance durability, corrosion resistance, and waterproofing for chemical tanks, wastewater containers, factory flooring, and high-exposure structural surfaces.

-

Material: Composite FRP (Fiberglass Reinforced Plastic) – lightweight, highly chemical-resistant, and long-lasting.

-

Application Areas:

-

Storage tanks (chemical, food-grade, clean water, wastewater, etc.)

-

Industrial factory floors (chemical, food, pharmaceutical, mechanical, etc.)

-

|

|

|

|

-

Benefit

-

Excellent chemical resistance

-

Effective waterproofing, easy to clean

-

Prolongs structure lifespan, lowers maintenance costs

-

Fast application, compatible with concrete, metal, and more

-

Waterproof Rooftops of apartment buildings

|

|

Waterproofing Food-grade factory floors

Water Tank Waterproofing

-

Guaranteed: quality, safety, and compliance with technical and environmental standards.

Tư Vấn Bán Hàng

0368.172.226 / 0834.473.166

Hỗ Trợ Kỹ Thuật

0338.020.530

Tư Vấn

Địa chỉ văn phòng hà nội

Let’s

An Tâm (ATNewtech) accompany you in building green, clean, and sustainable projects with high-quality FRP composite tank and coating systems certified to meet Vietnam’s environmental standards.

An Tâm (ATNewtech) – COMPLETE PEACE OF MIND, SUSTAINABILITY FOR THE FUTURE!

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank