Applications of Grease Traps in the Food Industry

In industrial kitchens, restaurants, and food processing facilities, grease and waste are the primary causes of drainage blockages and environmental pollution. Grease traps have emerged as an optimal solution to address this issue. This article provides detailed information on the functions, structure, and operation of grease traps, as well as their applications in the food industry.

1. What Is a Grease Trap?

A grease trap, also known as a grease interceptor, grease separator, or grease filter box, is a device designed to remove grease and solid waste from wastewater before it is discharged into the environment. This equipment is typically made from high-quality stainless steel or plastic, ensuring durability and excellent heat resistance.

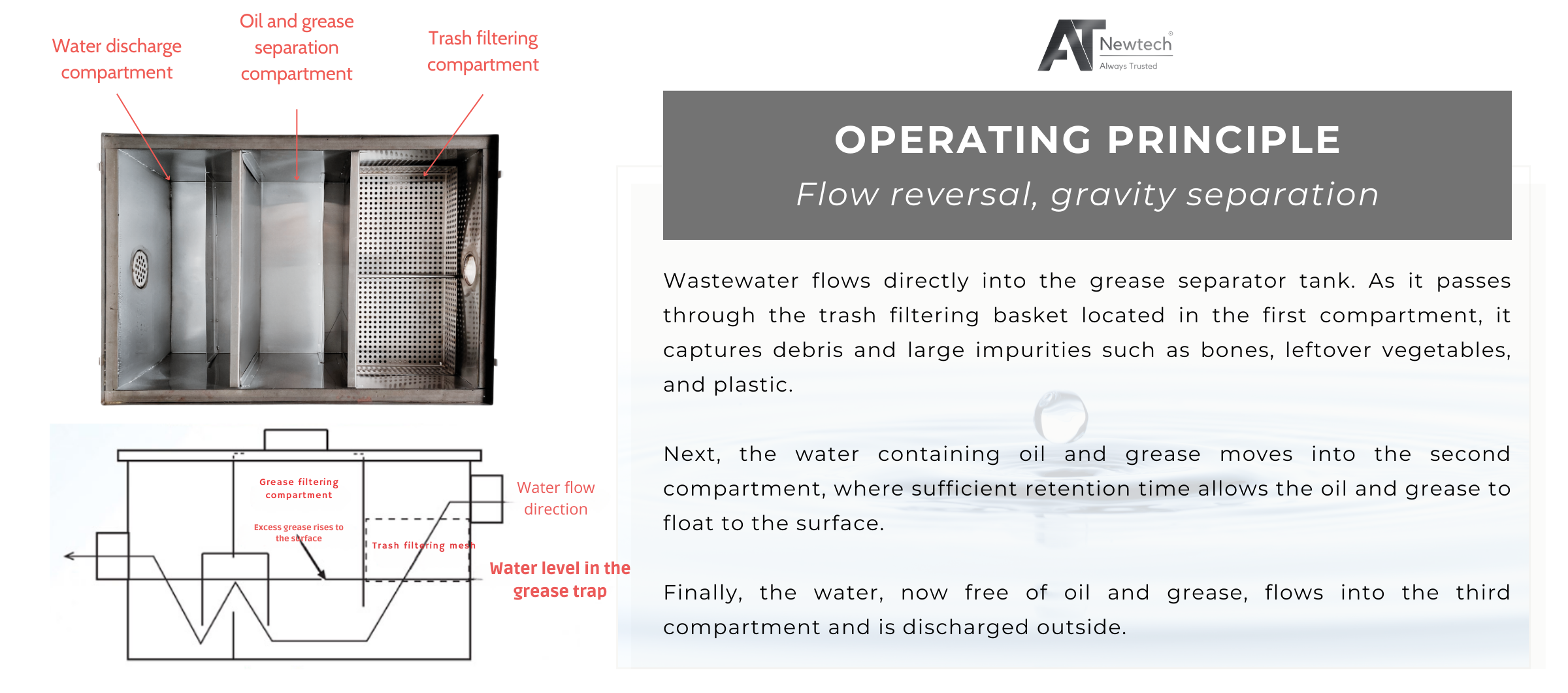

Basic Structure of a Grease Trap:

-

Waste Filter Compartment: Captures large solid waste such as leftover food.

-

Grease Separation Compartment: Uses gravity to separate grease, allowing it to float to the surface.

-

Clean Water Compartment: Allows treated wastewater to flow out safely.

-

Airtight Lid: Prevents odors from escaping and maintains hygiene.

2. Why Is It Necessary to Use a Grease Trap?

2.1 Protects the Drainage System

The drainage system in industrial kitchens often has to handle large amounts of wastewater containing grease and solid waste from food processing. Without timely treatment, grease will adhere to the inner walls of the pipes, combining with solid waste to form thick deposits. Over time, these deposits cause severe blockages, disrupting kitchen operations and leading to high repair costs. A grease trap helps remove grease and solid waste at the source, keeping the drainage system clear and functioning efficiently.

2.2 Ensuring Food Safety and Hygiene Standards

Industrial kitchen facilities such as restaurants, hotels, hospitals, or schools must strictly comply with hygiene standards. Improperly handled grease not only causes blockages but also creates an environment for bacteria to thrive, affecting food quality and the establishment’s reputation. Grease traps help maintain a clean kitchen environment, minimize contamination risks, and meet food safety standards.

2.3 Contributing to Environmental Protection

Grease discharged directly into the environment can cause severe pollution to water sources and ecosystems. It forms an oil layer that prevents oxygen from dissolving in water, harming aquatic life. Using a grease trap is a practical solution to minimize this negative impact, protect water sources, and maintain a clean and green environment.

2.4 Save time and Maintenance Cost

Drainage system blockages not only cause inconvenience but also require significant time and cost to resolve. Using a grease trap is a long-term investment that helps reduce maintenance frequency and save on repair costs. Additionally, grease traps are designed for easy cleaning without requiring complex technical skills, making maintenance simple for users.

2.5 Enhance the Operational Efficiency of the Kitchen

In industrial kitchens, operational efficiency is directly linked to the management of grease and wastewater. A clean, unclogged drainage system ensures a smooth and continuous food preparation process, minimizing disruptions and enhancing overall productivity. Grease traps play a crucial role in maintaining this seamless workflow.

3. Applications of Grease Traps in the Food Industry

3.1 In Restaurants and Hotels

Restaurant and hotel kitchens generate a large amount of grease and waste during food preparation. Grease traps help keep the drainage system clean, ensure food safety and hygiene, and enhance the overall efficiency of the kitchen.

3.2 In Food Processing Facilities

Food processing plants handle large amounts of grease and waste daily. Industrial grease separators are essential for ensuring that wastewater meets environmental standards before being discharged while also minimizing the risk of drainage system blockages.

3.3 In Communal Kitchens

In communal kitchens at schools, hospitals, or industrial zones, the use of grease traps helps maintain hygiene and prevents grease from affecting the overall drainage system.

4. How Grease Traps Work

Industrial kitchen grease traps operate based on the principle of gravity and the difference in density between grease, water, and solid waste. This process is divided into three main stages:

4.1 Solid Waste Retention:

-

-

Wastewater from the kitchen flows into the first compartment, where a filter or basket traps large solid waste such as food scraps, vegetable peels, and other debris.

-

This prevents solid waste from flowing into the next compartments, reducing the risk of pipe blockages.

-

4.2 Grease Separation Compartment:

-

After passing through the solid waste filter, wastewater containing grease flows into the second compartment. Here, since grease has a lower density than water, it rises to the surface and is retained in this section.

-

Some grease traps are designed with zigzag baffles to enhance grease separation and slow down the flow, allowing grease to settle more effectively.

-

4.3 Clean Water Discharge:

-

After grease separation, the wastewater flows into the final compartment before being discharged into the drainage system. This section is designed to ensure that the released water is free of grease and solid waste.

-

5. Benefits of Industrial Kitchen Grease Trap Systems:

-

Odor Prevention: The airtight lid helps minimize unpleasant odors generated during the grease separation process.

-

Easy Maintenance: The removable baffles and filter baskets allow for convenient periodic cleaning.

-

Flexible Adaptation: Depending on the kitchen’s scale, grease traps can be designed with appropriate capacity and structure to ensure optimal performance.

By operating through this process, grease traps not only keep the drainage system clear but also help protect the environment from grease-related pollution.

5.1 Based on Material

Select a grease trap made of stainless steel or high-quality plastic to ensure durability and excellent heat resistance.

5.2 Based on Capacity

Depending on the kitchen size, you can choose a compact sink grease trap for home use or an industrial grease separator for large restaurants.

5.3 Prioritize Reputable Brands

The Ecoprotec grease separator is a top choice due to its superior quality, convenient design, and effective grease management capabilities.

6. Ecoprotec – A Trusted Grease Trap Supplier

Ecoprotec offers grease trap products in various sizes and functionalities, catering to both household and commercial needs. Our products are of high quality, meeting safety and environmental hygiene standards.

-

Hotline: 0368172226 / 0834473166

-

Website: atnewtech.vn

Contact us today for detailed consultation and the best price offers!

Using a grease trap not only protects the drainage system but also plays a crucial role in environmental conservation. Invest today to experience outstanding efficiency!

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank