AAO Technology – A High-Efficiency, Low-Cost Wastewater Treatment Solution

As wastewater treatment requirements become increasingly strict, AAO (Anaerobic – Anoxic – Oxic) technology is emerging as an ideal solution for modern wastewater treatment systems. With the ability to simultaneously remove BOD, COD, nitrogen, and phosphorus, AAO not only meets Vietnam’s discharge standards but also optimizes operating costs, reduces sludge production, is easy to operate, and offers flexible design options.

1. Overview of the Growing Demand for Wastewater Treatment

With increasing environmental pollution—especially the contamination of water sources caused by domestic and industrial wastewater—the demand for effective treatment solutions is becoming more urgent. Among these, AAO technology is gaining widespread adoption thanks to its balance between high treatment efficiency and reasonable operational costs.

2. What is AAO Technology? Structure and Operating Principle

2.1. AAO: Anaerobic – Anoxic – Oxic

AAO stands for Anaerobic – Anoxic – Oxic. It is a biological wastewater treatment process that occurs in sequential stages. This method utilizes the decomposition and transformation capabilities of different groups of microorganisms under varying oxygen conditions to treat wastewater effectively.

-

Anaerobic (No oxygen): In this stage, complex organic compounds are broken down in the absence of oxygen, and phosphorus is released.

-

Anoxic (Low oxygen): This stage enables the denitrification process, where nitrate (NO₃⁻) is converted into nitrogen gas (N₂), helping remove nitrogen from the wastewater.

-

Oxic (Oxygen-rich): In this aerobic environment, microorganisms oxidize pollutants such as ammonia (NH₄⁺), organic matter (COD, BOD), and help eliminate odors.

2.2. Operating Principle of AAO Technology

-

Anaerobic Stage (No oxygen): Microorganisms break down organic matter in the absence of oxygen and release phosphorus.

-

Anoxic Stage (Low oxygen): Nitrate is converted into nitrogen gas through the denitrification process.

-

Aerobic Stage (Oxygen-rich): Microorganisms oxidize ammonia, treat COD and BOD, remove odors, and increase microbial biomass.

3. Key Advantages of the AAO Solution

-

Simultaneous removal of BOD, COD, ammonia, nitrate, and phosphorus

-

Reduced sludge production thanks to autotrophic microorganisms

-

Cost savings due to the oxygen/nitrate recycling process

-

Easy to operate and adaptable to load fluctuations

-

Suitable for various types of wastewater sources

4. Detailed Steps in the AAO Wastewater Treatment Process

-

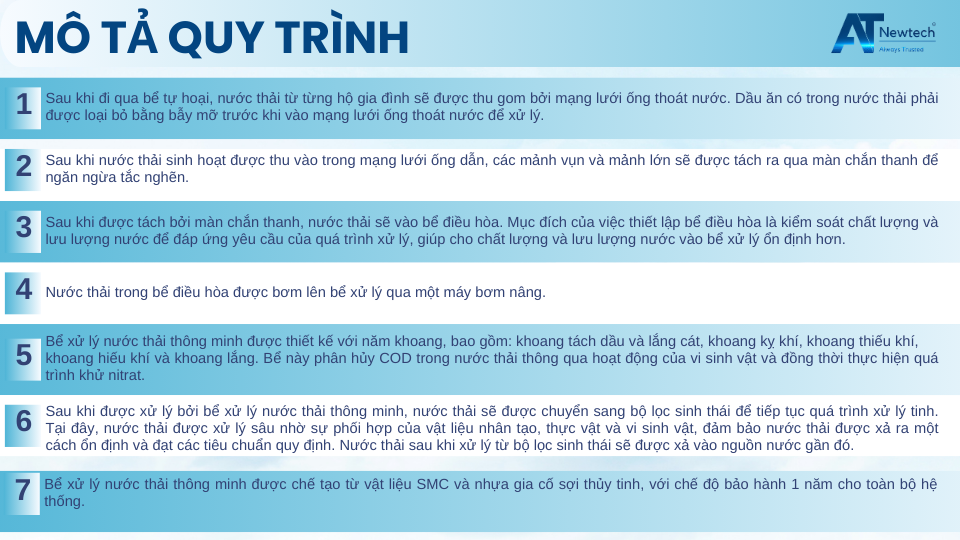

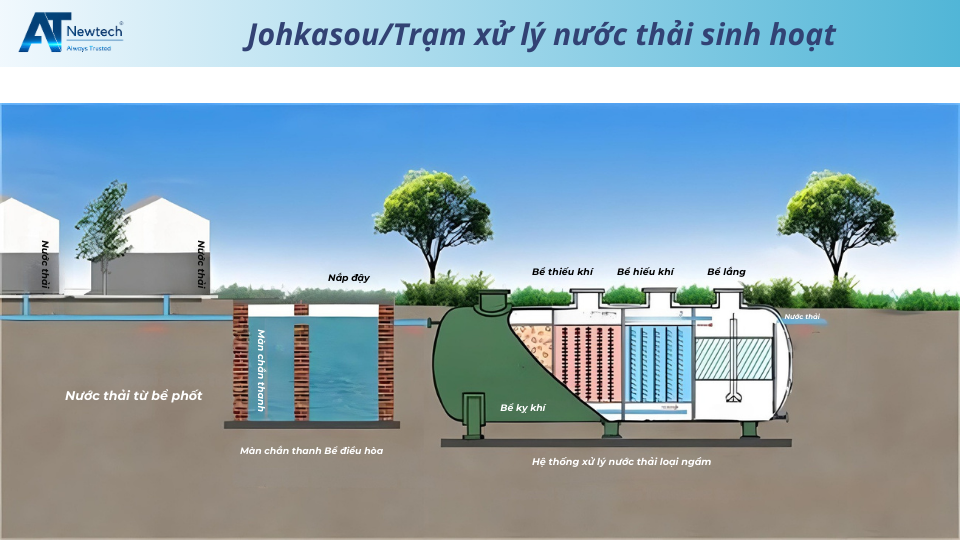

Step 1: Screening and Equalization

Remove coarse solids

Balance flow and load

Prevent shock loading -

Step 2: AAO Biological Treatment

Wastewater flows through three chambers: anaerobic → anoxic → aerobic

Each stage targets specific pollutants -

Step 3: Sludge Separation

Treated water moves to the settling tank

Biomass is recirculated

Excess sludge is directed for further treatment -

Step 4: Disinfection

Final treatment using chlorine, ozone, or UV

Ensures the effluent is safe before discharge

5. Real-World Applications of AAO Technology

-

Residential areas, apartment complexes, urban developments

-

Hospitals and medical stations

-

Food processing plants, textile and dyeing factories, livestock farms

-

Industrial zones and centralized wastewater treatment stations

6. Comparison of AAO with Other Treatment Technologies

| Criteria | AAO | MBBR (Moving Bed Biofilm Reactor) | Conventional Systems |

|---|---|---|---|

| Nitrogen & Phosphorus Removal | High Efficiency | Moderate | Low |

| Sludge Production | Low | High | High |

| Space Requirement | Medium | Small | Large |

| Operating Cost | Reasonable | High | High |

| Flexibility | High | Moderate | Low |

7. Combining AAO with Membrane Technology (MBR) for Enhanced Performance

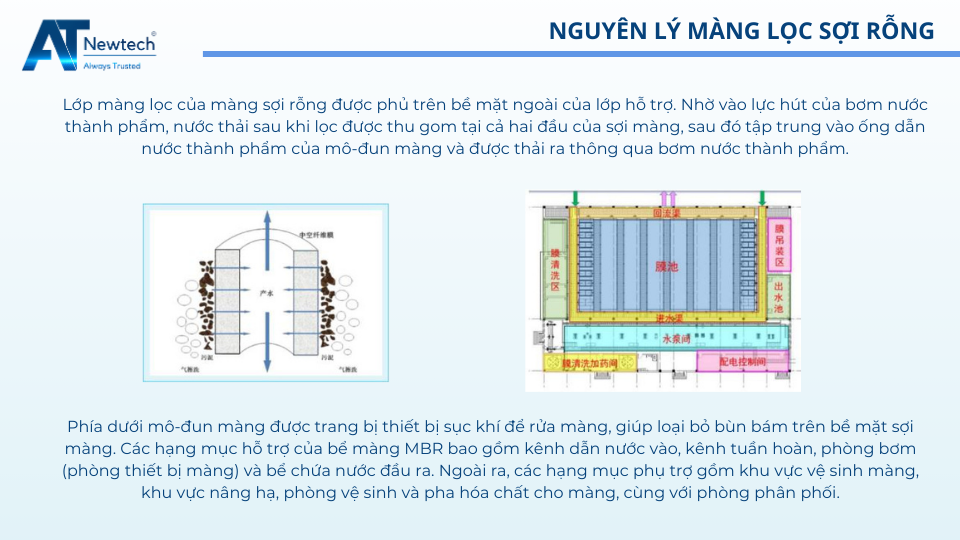

In today’s advanced wastewater treatment systems, combining AAO technology with MBR (Membrane Bio-Reactor) is becoming increasingly popular. This integration not only maximizes treatment efficiency but also addresses limitations that conventional AAO systems may not fully overcome.

7.1. What is MBR?

7.2. Benefits of Combining AAO with MBR

-

Enhanced Treatment Efficiency: The MBR membrane retains all microorganisms within the tank, increasing the MLSS (Mixed Liquor Suspended Solids) concentration. This significantly improves the removal of COD, BOD, ammonia, nitrate, and phosphorus.

-

High-Quality Effluent for Reuse or Discharge: Water treated through the AAO-MBR system can meet QCVN 14:2008/BTNMT, Column A standards—suitable for discharge into receiving bodies or reuse for irrigation and toilet flushing.

-

Space Saving Design: As no secondary settling tank is needed and higher sludge concentrations are allowed, the system requires significantly less space. This makes it ideal for urban areas and factories with limited land availability.

-

Stable Operation: MBR systems are less affected by fluctuations in influent load. The membranes ensure consistently high effluent quality, even under variable conditions.

7.3. Practical Applications of the AAO-MBR System

-

Wastewater treatment in high-rise apartment buildings, hospitals, and premium hotels

-

Food and pharmaceutical factories requiring high-quality effluent

-

Projects with strict discharge standards and limited available space

8. Design and Operation Considerations for AAO-MBR Systems

-

Properly design based on expected load

-

Configure AAO compartments logically

-

Maintain stable microbial activity

-

Monitor and control DO, pH, and temperature

-

Regularly maintain equipment and membranes

9. Featured Projects

10. Why Choose AT.newtech as Your AAO System Provider?

-

Years of industry experience

-

Optimized, flexible solutions tailored to each project

-

Full-package construction with long-term warranty

-

Guaranteed compliance with QCVN discharge standards

10. Conclusion

AAO technology is one of the most effective, stable, and cost-efficient biological wastewater treatment solutions available today. With its ability to simultaneously treat COD, BOD, ammonia, nitrate, and phosphorus—and its high adaptability—it suits a wide range of applications from residential to industrial systems.

If you’re looking for a reliable, sustainable, and economical wastewater treatment solution, let AT.newtech be your trusted partner.

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank