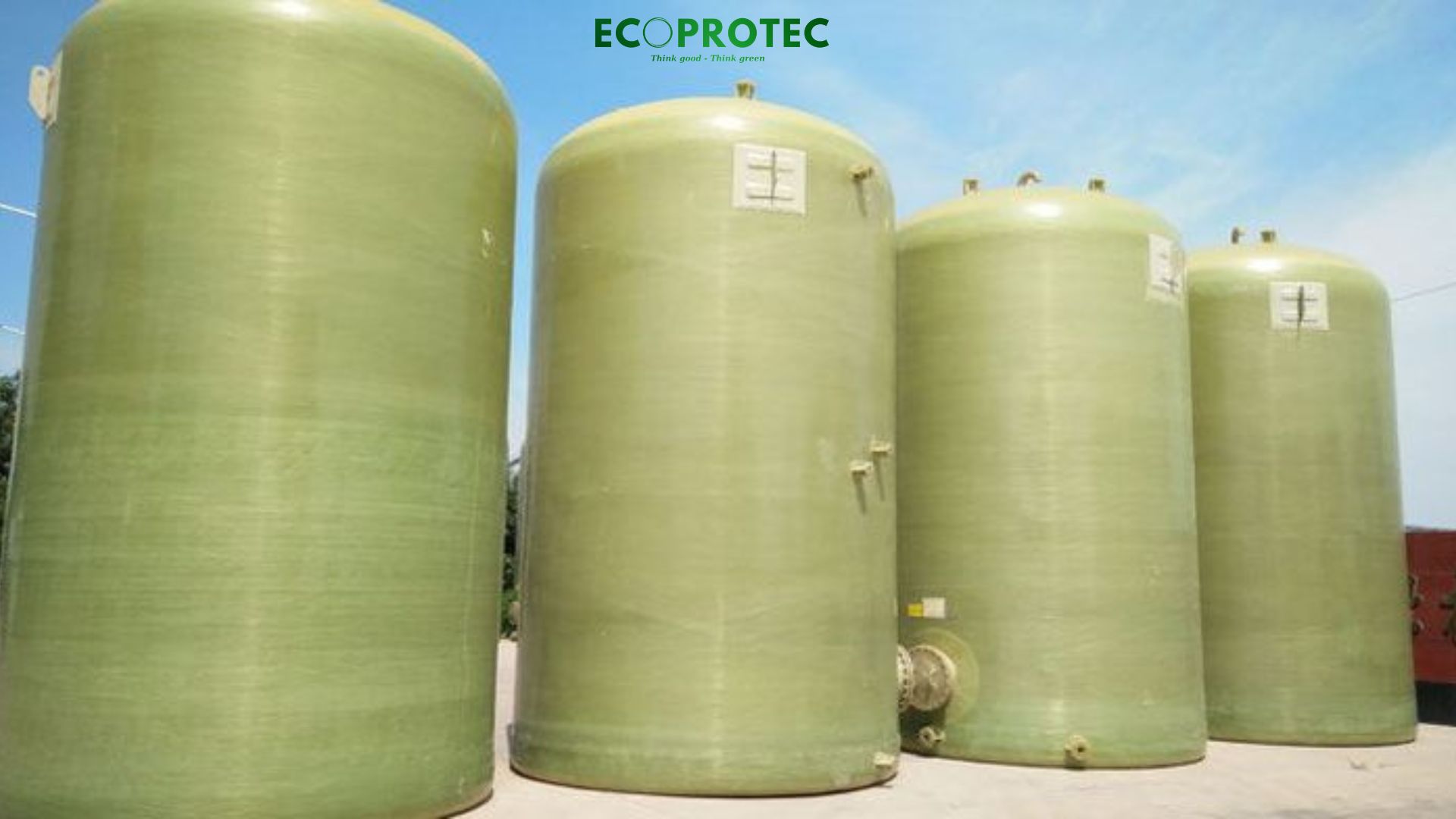

Is FRP Composite Sulfuric Acid (H₂SO₄) Storage Tank Safe?

Sulfuric acid (H₂SO₄) is one of the most highly corrosive chemicals, widely used in industrial production, wastewater treatment, and electroplating. Storing this acid is a major challenge—especially in outdoor environments or areas exposed to harsh corrosive elements. In recent years, composite FRP chemical tanks have become increasingly popular for storing H₂SO₄. But is an FRP composite tank really safe for sulfuric acid storage? Let’s explore this in detail with ATNewtech.

2. Overview of Sulfuric Acid (H₂SO₄) and Storage Requirements

2.1. Characteristics of H₂SO₄:

-

Extremely high corrosiveness, especially with metals

-

Causes severe burns upon skin contact

-

Reacts violently with water and organic substances

-

Can emit toxic fumes at high concentration and temperature

2.2. Tank requirements:

-

Must resist strong chemical corrosion

-

No rusting or chemical reactivity

-

UV-resistant if placed outdoors

-

Airtight, equipped with pressure relief valve or vent

-

Able to withstand pressure and operating temperature

3. FRP Composite – The Ideal Solution for H₂SO₄ Storage

FRP (Fiberglass Reinforced Plastic) is a composite material made of fiberglass and a resin matrix (typically Vinyl Ester or Polyester). It is highly valued in the chemical industry for the following characteristics:

Outstanding advantages:

-

Exceptional chemical resistance, especially against inorganic acids like H₂SO₄

-

Non-conductive, non-reactive—safe for both people and the environment

-

Lightweight—easy to transport and install

-

Long service life—15–20+ years with proper use

-

Can be reinforced with multiple layers depending on acid concentration and temperature

As a result, FRP composite chemical tanks are a superior alternative to traditional stainless steel or concrete tanks for storing sulfuric acid.

4. Is an FRP Composite Tank Truly Safe for H₂SO₄?

4.1. Structural safety features:

-

Inner lining made of Vinyl Ester resin for high permeability and corrosion resistance

-

Multi-layer (3–5 fiberglass layers) structure to withstand pressure and mechanical stress

-

Outer gelcoat layer protects against UV rays and environmental wear

-

Sealed cap and valves prevent gas leakage and ensure airtight operation

4.2. Manufacturing standards:

-

Complies with ASTM D3299, BS4994, ISO 9001 for chemical safety

-

Leak testing, mechanical durability, and pressure resistance certifications

4.3. In actual use:

Many ATNewtech customers have installed composite tanks for storing H₂SO₄ in electroplating factories, wastewater treatment plants, and more — and have used them safely and stably for 5–10 years without any signs of damage, cracks, or leaks.

5. Comparison: Composite FRP vs. 316L Stainless Steel for H₂SO₄ Storage

| Criteria | FRP Composite Tank | 316L Stainless Steel Tank |

|---|---|---|

| H₂SO₄ Corrosion Resistance | Excellent, resists up to 98% H₂SO₄ | Limited, prone to corrosion |

| Weight | Light | Heavy |

| Design Flexibility | Highly customizable | Limited |

| Cost | 30–40% lower | Higher |

| Lifespan | 15–20 years | 7–10 years (without careful maintenance) |

Conclusion: Composite FRP tanks are not only safer for storing H₂SO₄ but also more cost-effective and easier to maintain than stainless steel tanks.

6. Notes When Choosing a Tank for H₂SO₄ Storage

-

Use a Vinyl Ester-lined tank if storing high-concentration H₂SO₄ (above 70%)

-

Prioritize ventilation ports and safety drain valves

-

UV protection is essential for outdoor installations

-

Request technical certifications from the supplier (chemical resistance tests, technical drawings…)

-

Perform scheduled maintenance every 6–12 months to check linings and fittings

7. ATNewtech – Trusted Manufacturer of FRP Composite Chemical Tanks

With over 10 years of experience, ATNewtech is a leading provider of composite chemical storage tanks, especially for sulfuric acid H₂SO₄, offering key advantages:

-

Imported Vinyl Ester resin for superior acid resistance

-

Wide range of capacities: from 500L to 30,000L

-

Custom designs: vertical/horizontal tanks, heating, UV protection…

-

Nationwide delivery and installation, 3-year warranty

-

In-depth consultation for each chemical type and factory scale

📞 Hotline: 0834473166

🌐 Website: https://atnewtech.vn

8. Should You Choose FRP Composite for Storing H₂SO₄?

If you’re looking for a safe, durable, and cost-effective solution to store sulfuric acid (H₂SO₄), then a composite FRP tank is definitely worth considering. With excellent acid resistance, customizable designs, and long service life, it’s an essential solution for modern factories.

Don’t hesitate to contact ATNewtech for a free consultation and recommendation tailored to your chemical and operational needs.

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank