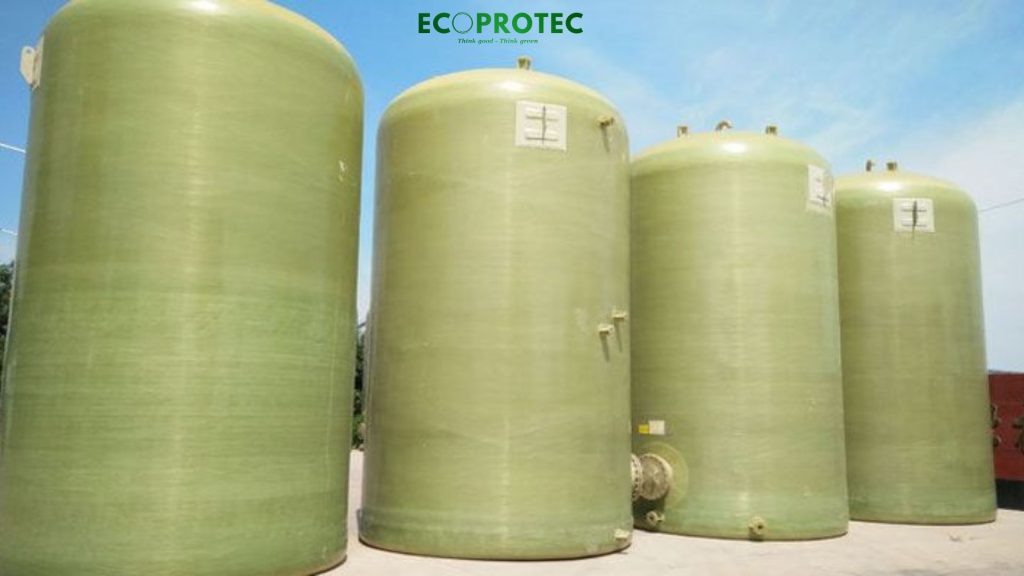

1000L FRP Chemical Storage Tank – A Smart Choice for Small and Medium-Sized Factories

For small and medium-sized factories, selecting the right chemical storage solution that is safe, cost-effective, and long-lasting is not an easy task. Among the available options, the 1000L FRP (Fiberglass Reinforced Plastic) chemical tank stands out as an optimal solution, highly rated by engineers and facility owners alike. This article provides an in-depth review of its technical specifications, features, durability, and cost advantages to help you understand why FRP composite tanks are the smart choice for mid-scale operations.

1. Why Choosing the Right Chemical Storage Tank Matters

In industrial production, chemicals like acids, alkalis, and solvents must be stored safely—ensuring no leakage, corrosion resistance, and stability under harsh environmental conditions. Choosing the wrong storage tank can lead to serious consequences:

-

Damage to surrounding equipment or infrastructure

-

Chemical leaks that threaten safety and the environment

-

Increased maintenance and replacement costs

For small and medium-sized factories, investing in the right storage tank from the start helps minimize long-term costs while ensuring production safety.

2. Overview of the 1000L FRP Chemical Tank

The 1000L chemical tank is manufactured from FRP (Fiberglass Reinforced Plastic), a combination of resin (typically Vinyl Ester or Polyester) and fiberglass.

2.1. Typical Technical Specifications:

-

Capacity: 1000 liters

-

Design: Vertical or horizontal cylindrical structure

-

Material: FRP composite with Vinyl Ester or Polyester core

-

Inner Layer: High chemical resistance (suitable for acids, alkalis, salts, etc.)

-

Outer Coating: UV-resistant, impact-resistant, thermal insulation

2.2. Key Advantages:

-

✅ Lightweight – Easy to transport and install

-

✅ Excellent chemical resistance, including strong acids like H₂SO₄ and bases like NaOH

-

✅ Non-corrosive – Unlike metal tanks, it won’t rust

-

✅ Long lifespan – 15 to 20 years with proper use

-

✅ Low maintenance costs

3. FRP vs. Stainless Steel in Chemical Storage

| Criteria | FRP Composite Tank | 316L Stainless Steel Tank |

| Strong acid resistance (H₂SO₄, HCl) | Excellent (especially with Vinyl Ester) | Limited – prone to corrosion at high concentrations |

| Weight | Light | Heavy |

| Cost | Lower cost | 1.5–2 times more expensive |

| Outdoor durability | 15–20 years with UV protection | Susceptible to rust without regular maintenance |

| Customizability | Highly flexible design | Limited customization |

Conclusion: With a 1000L capacity and industrial chemical storage requirements, FRP composite tanks offer a more reliable and economical solution compared to stainless steel tanks in most scenarios.

4. 1000L Sulfuric Acid Tank – Should You Use FRP Composite?

The answer is yes, but only if the right resin is used. For strong acids like H₂SO₄, the tank must be made with:

-

Vinyl Ester Resin: Offers superior acid resistance compared to standard polyester.

-

Inner Lining Thickness: Must meet industry standards to prevent chemical permeation.

-

Structural Design: Must withstand heat and pressure if the chemical is stored in hot or reactive states.

FRP composite acid tanks are increasingly chosen by chemical manufacturers due to their excellent corrosion resistance, long lifespan, and cost-efficiency.

5. Durability & Lifespan of a 1000L FRP Chemical Tank

Depending on operating conditions (temperature, weather, chemical type), an FRP composite tank can last up to 20 years, provided that:

-

It’s manufactured correctly with sufficient FRP reinforcement.

-

UV-resistant gelcoat is applied externally.

-

Regular maintenance is performed: check surfaces, linings, fittings, drain valves…

Many ATNewtech customers have used 1000L FRP tanks outdoors for over 10 years without replacement.

6. Investment Cost – Is FRP Really More Economical?

Average cost for a 1000L FRP chemical tank:

-

6–10 million VND, depending on resin type, thickness, and design.

-

30–50% cheaper than a stainless steel tank of the same capacity.

-

Minimal maintenance costs: no rust, no need for frequent repainting.

For small to medium-sized factories, this is a smart long-term investment—avoiding high upfront costs for oversized or incompatible steel equipment.

7. Tips for Choosing the Right 1000L Chemical Tank

-

Identify the type of chemical: acid, base, salt, solvent, etc.

-

Ask the supplier for chemical compatibility test reports or technical catalogues.

-

Vinyl Ester lining is recommended for storing strong acids.

-

For outdoor installations, choose UV-protected options.

-

Consider extra features: locking lid, sight glass, FRP support legs, etc.

8. ATNewtech – Trusted FRP Chemical Tank Manufacturer in Vietnam

With over 10 years of experience in manufacturing and installing FRP chemical storage tanks, ATNewtech offers:

-

Wide product range: from 500L to 30,000L

-

Free consultation based on your chemical type and installation site

-

Nationwide delivery, up to 3-year warranty

-

On-site installation and technical support

👉 Hotline: 0834473166

👉 Website: https://atnewtech.vn

👉 Website: https://atnewtech.vn

9. Why the 1000L FRP Composite Tank is a Smart Choice

-

Ideal for small to medium-sized chemical plants

-

Reasonable investment cost, high durability, easy to install

-

Superior resistance to corrosion: H₂SO₄, NaOH, HCl, and more

-

Safe – Aesthetic – Cost-effective in the long run

If you’re still unsure which tank to choose for your plant, the 1000L FRP chemical tank is definitely worth your consideration today.

Composite Tank

Composite Tank Water tank cover.

Water tank cover. Kitchen equipment

Kitchen equipment Industrial water tank

Industrial water tank